Products

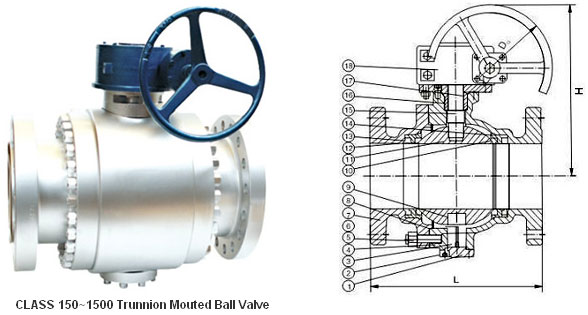

Class 150~1500 Trunnion Mounted Ball Valve

Product Description

Class 150~1500

Design and Manufacture: API 6D, API 608, ANSI B16.34 or BS5351

Face to Face Dimensions: ANSI B16.10

Pressure-Temperature Ratings: ANSI B16.34

Test: API 6D or API 598

End Flange Dimensions:

NPS 2~24: ANSI B16.5

NPS 28: ANSI B16.47 or MSS SP-44

Type of Connection:

RF and RTJ flange ends to ANSI B16.5 or API 605 and MSS SP-44 standard.

BW flange ends to ANSI B16.25 standard.

Type of Operation

Lever

Connection dimensions of Worm Gear actuator, Electric actuator, Pneumatic actuator to ISO 5211 standard.

Anti-static electricity constructions "AS" and Fire-safe constructions "FD" |

Standard Material Specifications

|

NO.

|

Part Name

|

Carbon Steel to ASTM

|

Stainless Steel to ASTM

|

|

WCB

|

LCB

|

CF8

|

CF8M

|

CF3

|

CF3M

|

|

1

|

Underplate

|

WCB

|

LCB

|

CF8

|

CF8M

|

CF3

|

CF3M

|

|

2

|

Underplate Bolt

|

A193 B7

|

A320 L7

|

A193 B8

|

|

3

|

Trunnion

|

A182 F6

|

A182 F6

|

A182 F304

|

A182 F316

|

A182 F304L

|

A182 F316L

|

|

4

|

Body

|

A216 WCB

|

A352 LCB

|

A351 CF8

|

A351 CF8M

|

A351 CF3

|

A351 CF3M

|

|

5

|

Bonnet Nut

|

A194 2H

|

A194 4

|

A194 8

|

|

6

|

Bonnet Bolt

|

A193 B7

|

A320 L7

|

A193 B8

|

|

7

|

Cap

|

A216 WCB

|

A352 LCB

|

A351 CF8

|

A351 CF8M

|

A351 CF3

|

A351 CF3M

|

|

8

|

Gasket

|

SS Spiral Wound/Graphite or SS Spiral Wound/PTFE

|

|

9

|

Shaft Sleeve

|

SS /Graphite

|

|

10

|

Seat Ring

|

RPTFE or POM

|

|

11

|

Ball

|

A105/Ep.Cr or F6

|

A182 F6

|

A351 CF8

|

A351 CF8M

|

A351 CF3

|

A351 CF3M

|

|

12

|

Seat

|

A105/Ep.Cr or F6

|

A182 F6

|

A182 F304

|

A182 F316

|

A182 F304L

|

A182 F316L

|

|

13

|

Spring

|

17-17PH (inconel for NACE) Ni-Cr Alloy

|

|

14

|

O-Ring

|

Viton

|

|

15

|

Stem

|

A182 F6

|

A182 F6

|

A182 F304

|

A182 F316

|

A182 F304L

|

A182 F316L

|

|

16

|

Sealing Cover

|

A182 F6

|

A182 F6

|

A182 F304

|

A182 F316

|

A182 F304L

|

A182 F316L

|

|

17

|

O-Ring

|

Viton

|

|

18

|

Gear Actuator

|

|

Dimensions (mm) And Weights (kg)

|

Class

|

DN

|

mm

|

50

|

65

|

80

|

100

|

150

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

600

|

700

|

|

NPS

|

in

|

2

|

2-1/2

|

3

|

4

|

6

|

8

|

10

|

12

|

14

|

16

|

18

|

20

|

24

|

28

|

|

150

|

L(RF)

|

mm

|

178

|

191

|

203

|

229

|

394

|

457

|

533

|

610

|

686

|

762

|

864

|

914

|

1067

|

1245

|

|

in

|

7

|

7.5

|

8

|

9

|

15.5

|

18

|

21

|

24

|

27

|

30

|

34

|

36

|

42

|

49

|

|

L1(BW)

|

mm

|

216

|

241

|

283

|

305

|

457

|

521

|

559

|

635

|

762

|

838

|

914

|

991

|

1143

|

1346

|

|

in

|

8.5

|

9.5

|

11.13

|

12

|

18

|

20.5

|

22

|

25

|

30

|

33

|

36

|

39

|

45.5

|

53

|

|

L2(RTJ)

|

mm

|

191

|

203

|

216

|

241

|

406

|

470

|

546

|

622

|

699

|

775

|

876

|

927

|

1080

|

|

|

in

|

7.5

|

8

|

8.5

|

9.5

|

16

|

18.5

|

21.5

|

24.5

|

27.5

|

30.5

|

34.5

|

36.5

|

42.5

|

|

|

H

|

mm

|

153

|

165

|

195

|

213

|

272

|

342

|

495

|

580

|

625

|

720

|

790

|

840

|

1050

|

1150

|

|

in

|

6.02

|

6.5

|

7.68

|

8.39

|

10.7

|

13.5

|

19.5

|

22.85

|

24.6

|

28.35

|

31

|

33.1

|

41.34

|

45.3

|

|

Do(W)

|

mm

|

400

|

400

|

600

|

850

|

1100

|

1500

|

350*

|

350*

|

600*

|

600*

|

800*

|

800*

|

800*

|

800*

|

|

in

|

15.74

|

15.74

|

23.62

|

33.46

|

43.3

|

59

|

13.8

|

13.8

|

23.6

|

23.6

|

31.5

|

31.5

|

31.5

|

31.5

|

|

WT(Kg)

|

RF

|

15

|

19

|

38

|

65

|

97

|

160

|

240

|

390

|

510

|

750

|

895

|

1190

|

2100

|

3000

|

|

BW

|

13

|

17

|

35

|

55

|

92.8

|

154

|

227

|

365

|

478

|

711

|

868

|

1138

|

2015

|

2900

|

|

Class

|

DN

|

mm

|

50

|

65

|

80

|

100

|

150

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

600

|

700

|

|

NPS

|

in

|

2

|

2-1/2

|

3

|

4

|

6

|

8

|

10

|

12

|

14

|

16

|

18

|

20

|

24

|

28

|

|

300

|

L(RF)

|

mm

|

216

|

241

|

283

|

305

|

403

|

502

|

568

|

648

|

762

|

838

|

914

|

991

|

1143

|

1346

|

|

in

|

8.5

|

9.5

|

11.13

|

12

|

18

|

20.5

|

22

|

25

|

30

|

33

|

36

|

39

|

45.5

|

53

|

|

Related Products